In today’s world, precision and personalization are paramount, whether in art, manufacturing, or product branding. One of the key technologies that have revolutionized these industries is laser engraving. Laser engraving machines utilise the power of focused light to offer an efficient and versatile solution for etching intricate designs onto various materials. In this blog post, we’ll delve into the fascinating world of laser engraving machines, exploring how they work and their incredible benefits to a wide range of applications.

The Basics Of Laser Engraving

Laser engraving is a process that involves using a high-powered laser beam to mark, etch, or cut materials with exceptional precision. The process starts with a digital design, which translates into instructions for the laser engraver machine. These instructions dictate the path and intensity of the laser beam, allowing for the creation of intricate patterns, designs, and even text on different surfaces.

Laser engraving machines can work with various materials, including wood, metal, glass, acrylic, leather, and even certain plastics. The adaptability of these machines makes them versatile tools in multiple industries, ranging from arts and crafts to industrial manufacturing.

How It Works

- Laser Source: The heart of a laser engraving machine is the laser source itself. The laser produces a focused beam of light with high energy. Common types of lasers used in engraving machines include CO2 and fibre lasers, each with unique characteristics and applications.

- Focusing Optics: Before the laser beam is directed towards the material, it passes through a series of focusing optics. These optics ensure the laser beam is concentrated into a small, precise point. The focused beam is what allows for the fine detailing and accuracy of the engraving.

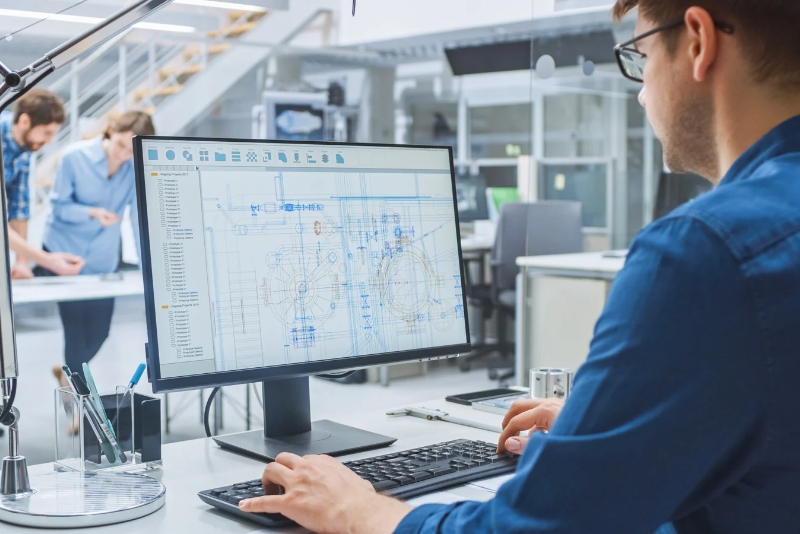

- X-Y Axis System: Laser engraving machines utilise an X-Y axis system, similar to a Cartesian coordinate system, to move the laser head over the material. The digital design guides the movement of the laser head as it traces the desired pattern onto the material’s surface.

- Material Interaction: When the focused laser beam comes into contact with the material, it interacts with the surface differently depending on its properties. For instance, on metals, the heat from the laser can cause the material to melt and vaporise, resulting in a deep and permanent mark. The heat can cause localised burning of wood, creating a contrasting effect.

- Cooling and Exhaust: As the laser generates heat during engraving, cooling and exhaust systems are essential to maintain optimal operating conditions. These systems ensure that the machine doesn’t overheat and that any fumes or debris produced are safely removed.

Benefits of Laser Engraving

- Precision: Laser engraving offers unmatched precision, allowing for intricate designs and even micro-engravings on various materials. This precision is especially crucial in industries where accuracy is paramount.

- Versatility: Laser engraving machines can work with various materials, making them invaluable in diverse sectors such as jewellery making, industrial manufacturing, and personalization services.

- Speed and Efficiency: Laser engraving is faster and more efficient than traditional engraving methods. It eliminates the need for physical contact between the machine and the material, reducing wear and tear on the equipment.

- Durability: Laser-engraved markings are more durable and resistant to fading, making them ideal for items subjected to wear and tear over time.